Want to stand out from the crowd? Enhance your brand image and add professionalism to your print materials with custom die cut designs. Carta Finishing provides the finishing touches that bring your projects to life!

.Carta Finishing can die-cut and assemble your products faster than any other SE Michigan print finishing company. We have the equipment and the bandwidth to support quick turnaround times. Once the cutting die has been created using our CAD rendering software and developed into a physical shape, we can assemble your product or packaging quickly, including handling all of the folding and hot, cold, or fugitive gluing that may come with it.

At Carta Finishing, we're capable of kiss-cutting packaging labels, business stickers, and more to allow for easy removal and bulk manufacturing. Perforation is ideal for clients who would like to include labels or coupons in their mail offerings, any sort of tickets or tags that need to be attached to something, or similar uses. We have machines that perfectly perf your materials to make for easy separation and clean tears every time.

If you are unsure of what you want your finalized product to look like, or you are interested in having a product die-made, our team of engineers will help you develop a CAD rendering of your product. We have worked with companies across Michigan and into the Midwest USA to create packaging for their products.

We start off with a consultation or initial call to hear about what you need and discuss the creative parameters. Then, our team gets to work creating a rendering that we will show you for your seal of approval. We then proceed to manufacture a sample of the die-cut stickers, product, or package. Once you check it out and give your final approval, we move forward with fully manufacturing the product quickly.

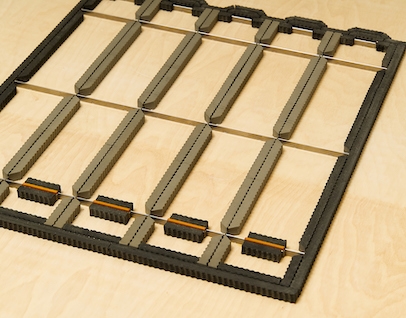

With Carta Finishing's CAD die-making services, you can design custom die to create shapes that enhance the appeal of your printed products, packaging, and more. Cut intricate shapes and detailed designs with high precision and speed—the possibilities are endless!

Here's how the die-cutting and custom die-making process works:

Show us your design or work with us to create one! Send over a digital file, a sketch, or a physical sample of the desired cut, and we'll get to work.

Next, our die maker creates a custom die to match your design or shape.

Finally, the material is fed into the die-cutting machine. The auto-stripping device automatically separates the waste parts from the useful parts, saving time and labor. The finished pieces are then collected and separated from the excess material.

Our digital die-cutting process uses a computer-controlled blade or laser to cut shapes from the material. Before the computer-aided design and convenience of digital die cut machines, however, the die-making process went through several incarnations:

Manual die cutting: A manual die cutter used a hand-operated crank or lever to press the sharp blade of a metal die against the material to cut out the shape.

Flatbed die cutting: Flatbed die cutters used a hydraulic or electric press to apply pressure on a flatbed die and the material to cut out the shape. This method was ideal for processing thicker materials, such as cardboard, rubber, or metal.

Semi-rotary die cutting: Semi-rotary die cutting machines employed a hybrid method that combined the features of rotary and flatbed die cutting. A motor controlled the movement of the material and the rotation of the die in a synchronized manner. The material moved back and forth while the die rotated in one direction. This allowed one common magnetic die to be used for multiple sizes and shapes. The speed and position of the die cuts could be adjusted according to the registration marks on the material.

Every team member at Carta Finishing is committed to quality control and customer service, making us the standout choice for die cutting, folding, and gluing in Metro Detroit. We’re always prepared to tackle high-volume commercial binding jobs with fast turnaround and excellent quality. Contact us to request a quote for die cutting services today!

We offer services to companies throughout southeast Michigan and the Midwestern United States from right in Roseville, MI.

We provide the print industry with some of the fastest commercial binding services available. Have a rush job or tight deadline? No problem.

Trying to maintain an in-house bindery department can be expensive. Learn how outsourcing to Carta Finishing can save you time and money by requesting a quote today!