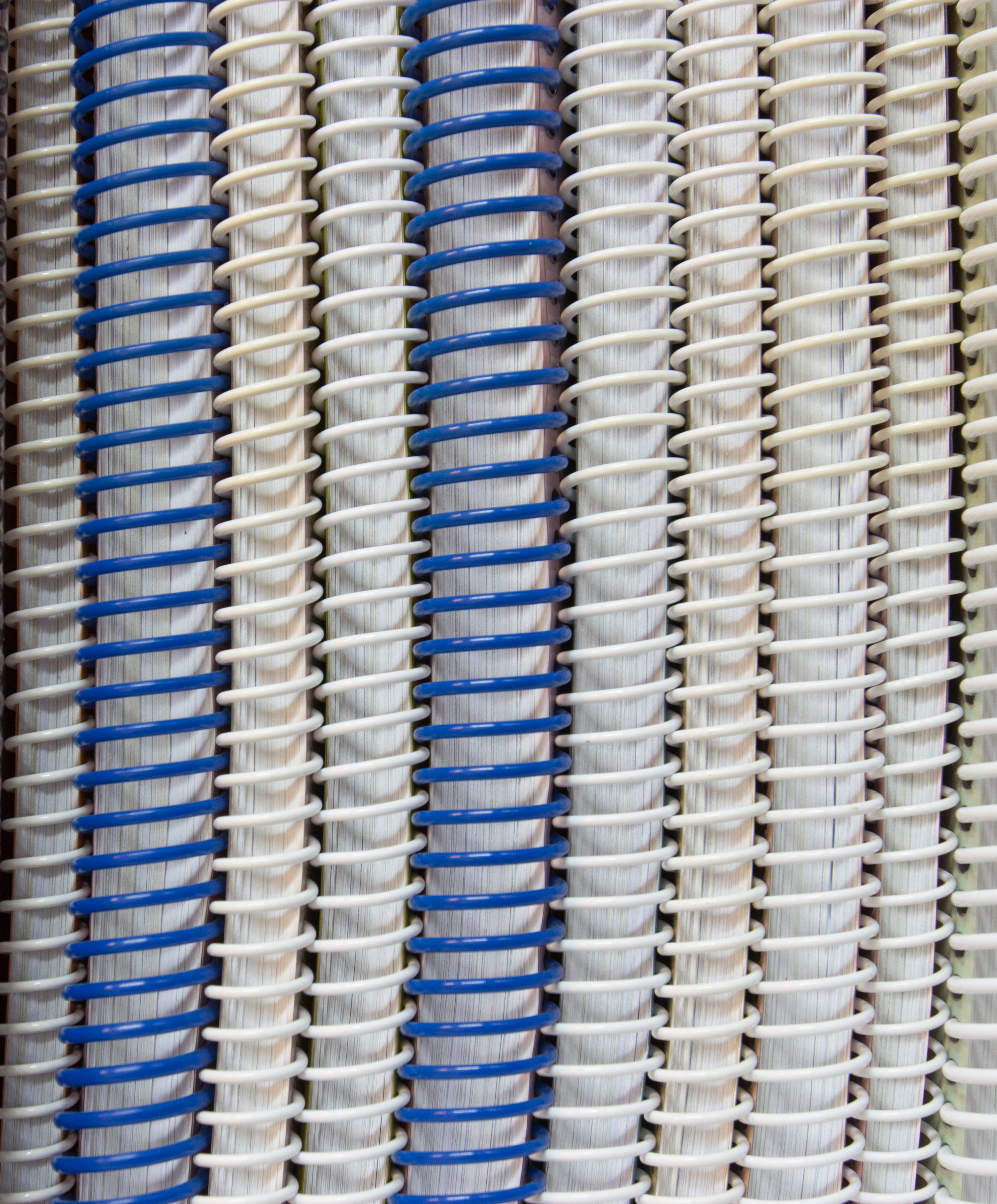

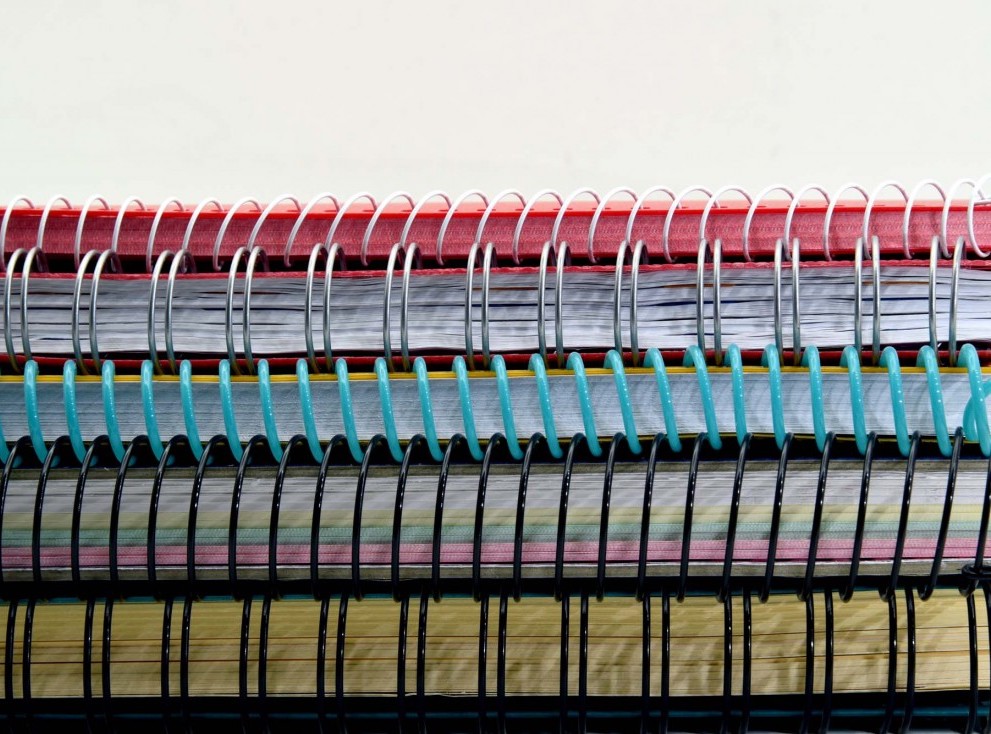

By using plastic spirals and wire-o’s through punched holes along the spine, the mechanical binding method holds books together without the need for glue or stitching.

One primary benefit is that this allows a book to lay flat, making mechanical binding a popular binding choice for workbooks and educational resources such as instruction manuals, cookbooks, calendars, and notebooks. This is perhaps the most cost-effective option of the binding services, especially in short runs.

At Carta Finishing, we provide binding and print finishing services to meet a variety of needs and aesthetics. Our recommendations for how to bind your book or other printed material will depend on the thickness, the type of cover, the intended use, and other factors.

In addition to saddle stitching, perfect binding, and glue binding, we also offer multiple mechanical binding options for your printed materials. Mechanical binding utilizes heavy machinery to punch holes into the book block and thread a plastic through the holes along the binding edge. This method is precise and results in a durable, sleek finished product.

The biggest advantage of spiral binding compared to wire-o binding is that it is much more durable. Because they are bound with so many joints in the spiral, sheets are less likely to fall out or become damaged as a result of the binding. If you or your customer plan to refer to the product you are binding a lot, we recommend considering spiral binding so it holds up to routine wear and tear.

We offer services to companies throughout southeast Michigan and the Midwestern United States from right in Roseville, MI.

We provide the print industry with some of the fastest commercial binding services available. Have a rush job or tight deadline? No problem.

Trying to maintain an in-house bindery department can be expensive. Learn how outsourcing to Carta Finishing can save you time and money by requesting a quote today!